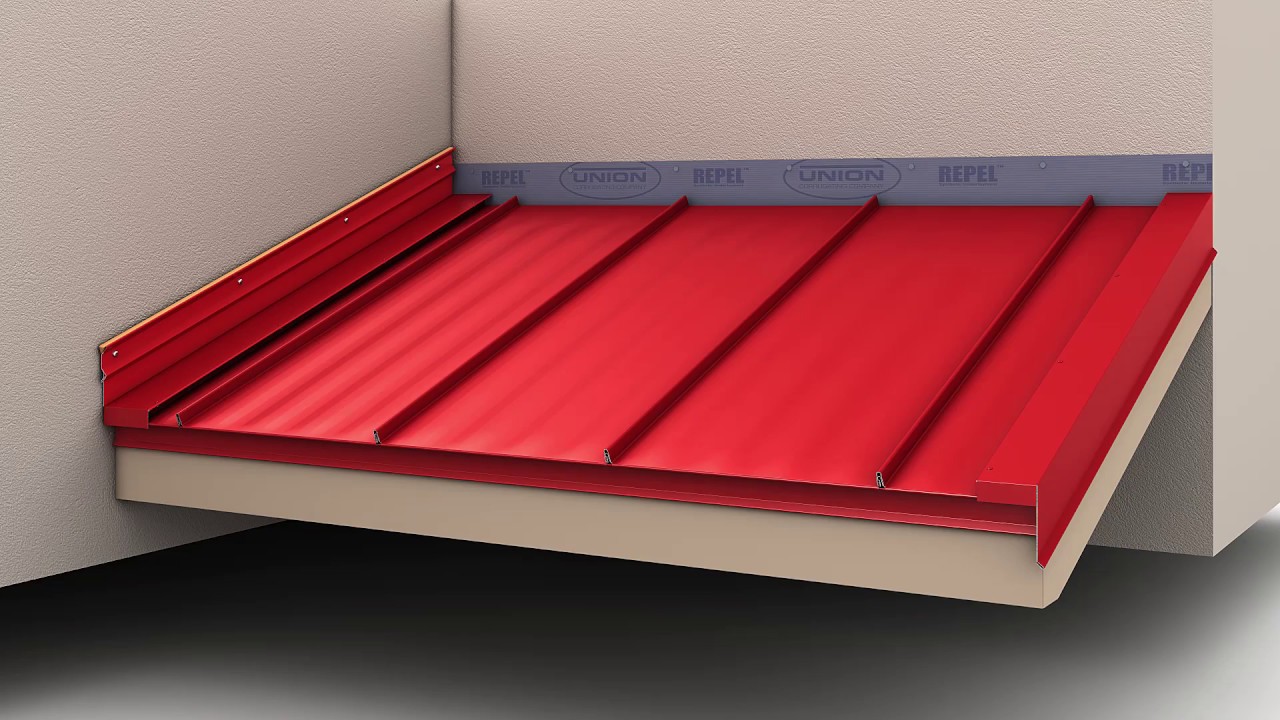

end wall flashing for metal roof

For front end-walls where roofing shingles meet siding the metal flashing strip should be bent using a metal brake to extend at least 2 inches up the vertical wall and at least 3 inches onto the last shingle course. Start Your Project Sooner with Store Pickup.

How To Install Metal Roof Rake Trim For Union S Masterrib Panel Youtube Metal Roof Standing Seam Metal Roof Metal Roof Installation

Install outside closures where the flat of the endwall flashing will be fastened to the roofing panels.

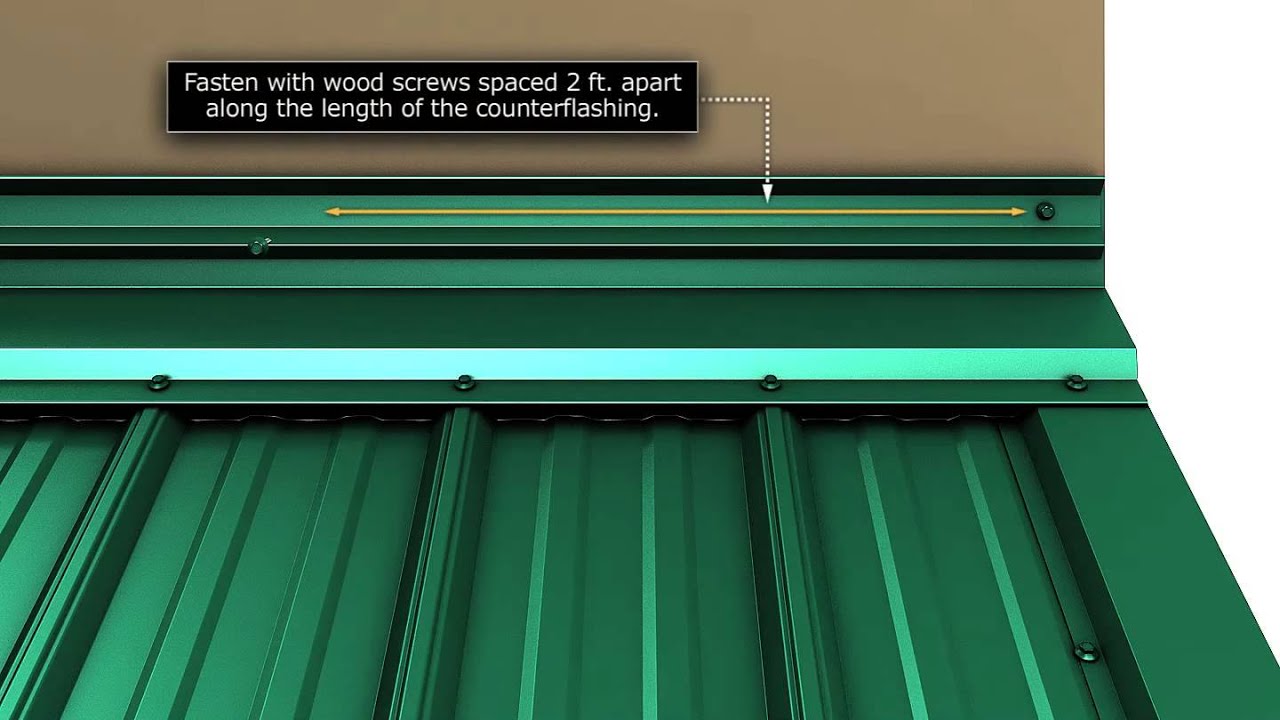

. The final preparation before fastening the flashing is to apply tape sealant to the top of the Z-trim. Endwall Flashing Installation Steps. The wall side of the flashing can be covered with siding or counter-flashing and outside closures are necessary to seal between the flashing and the panel.

Attach endwall flashing to roofing panels using 9 x 2 woodgrip fasteners 9 on-center every rib to prevent dimpling of endwall flashing. This color matched flashing also provides a professional finishing touch to your roof. 000 H x 000 W x 12000 D.

End-wall flashing is applied where the upward slope of a roof meets a wall. The End Wall Flashing provides protection where a roof intersects with a vertical wall. Ad Shop Roof Flashings Today Get Great Deals On Quality Products.

Ad Browse discover thousands of brands. Start by marking the pitch angle of your roof on the top edge of your sidewall starting at the corner of the trim. Ad Buy Our Products Online and Enjoy Free Store Pickup at Your Local Ace Hardware.

Step By Step Endwall Flashing Installation Instructions On A Metal Roof. Endwall flashing is applied where the upward slope of a roof meets the wall. Make a parallel line 1 from your first mark.

Specify which trim piece is needed and the roof pitch when ordering. Flashing and Coping RidgeHip Flash Part Length Gauge Girth Weight Each AG-202 10-2 29 13 837 AG-203 20-2 29 13 1674 RidgeHip Part General Length Gauge Girth Weight Eac Home Products Components Trim Exposed Fastener Panel Sidewall and Endwall Trim. Using metal cutting snips remove the sections marked with an X.

Explore a Wide Range of Quality Products to Fix Repair Maintain Your Home. Installation Instructions For Endwa. Striations and bends on the flashing provide strength and match the lines of your other edge trims.

Applying base flashing to a front wall where asphalt shingles meet the front wall siding. Our host David Mackey discusses techniques used in installing Endwall Trim using the SL-16 standing seam roofing system from American Building Components. Read customer reviews find best sellers.

Ad Only The Finest Metal And Roofing Supplies Since 1994. End-wall flaShIng End-wall flashing is applied where the upward slope of a roof meets the wall. If thats the case read this quick primer on how to install the following metal roof flashings on your home.

Install Metal Roof Endwall Trim At The Sidewall. On the lower section of the sidewall flashing mark a straight line across from your angled 1 line. 10 Long Length 26 Gauge Metal Matches color of panel Use with OUTSIDE CLOSURES HOW MANY DO I NEED.

The ensures that theres a watertight barrier between the end wall flashing and the top of the Z. Endwall flashing for residential agricultural and light industrial projects. Metal roofs are an excellent solution for buildings with complicated shapes.

Buy metal roofing available in a wide range of colors from Mackey Metal Roofing. They are light but capable of supporting enormous weights. SEALING FLASHING DETAILS ON METAL ROOFS Metal roofs Main advantages and disadvantages A metal roof is a roofing system made from metal pieces or tiles lightweight with high resistance weatherproof and durable.

The wall side of the endwall flashing can be covered with siding or counter-flashing and outside closures are necessary to seal between the flashing and the panel. Endwall flashing metal roof trim for roofing trim and metal roofing projects. Endwall flashing is to be used where there is a lean-to type roof sloping away from the vertical wall.

Universal End wall Trim is designed to flash from the high side of the metal roof panels to a vertical wall such as the front of a dormer. ADD UP THE TOTAL LINEAR FEET OF ENDWALL NEEDED AND DIVIDE BY 95 Click the link below to see an installation guide for Endwall Flashing. Find the Right Material For Every Job.

Prepainted Galvalume steel with a 25-year corrosion warranty and a 40-year paint warranty. The Universal End wall Trim combined with sealant provides a watertight seal for your roof system. Prepainted Galvalume steel with a 25-year corrosion warranty and a 40-year.

Its placed behind the wall steel and on top of the roof steel. Quick Same-Day Shipping Anywhere. Used in conjunction with closure strips or butyl tape it reliably protects against water infiltration.

Roof slope should be mentioned and specify which trim piece needed when ordering. By folding down the flashing you keep water from rolling between the top of the gable trim and the end wall flashing. Gibraltar End Wall Flashing can be used with most metal roofing.

Its end needs to be cut angled and. Rake trim is placed along the roofline where the line meets the gable. The wall side of the flashing can be covered with siding or counter-flashing and outside closures are necessary to seal between the flashing and the panel.

How To Install Endwall Trim For Union S Masterrib Panel Metal Roof Installation Roof Installation Roof Truss Design

10 6 Aluminum Steel Metal Trim Siding Brake 26g Steel Stand Slitter Included Ebay Sheet Metal Roofing Sheet Metal Work Siding Trim

Standing Seam Painted Steel Roof Wider View Of Chimney And Window Pan Metal Roof Installation Metal Roofing Prices Standing Seam